How an Excavator Winch Attachment Can Transform Your Jobsite

In heavy equipment operations, efficiency defines success. Every minute spent waiting for recovery equipment or repositioning a machine adds cost and slows progress. That’s why contractors are looking for smarter, more versatile solutions to do more with what they already have. At Midwestern Manufacturing, we design equipment that empowers operators to maximize performance without compromise—and one of the most effective upgrades to achieve that is an Excavator Winch Attachment.

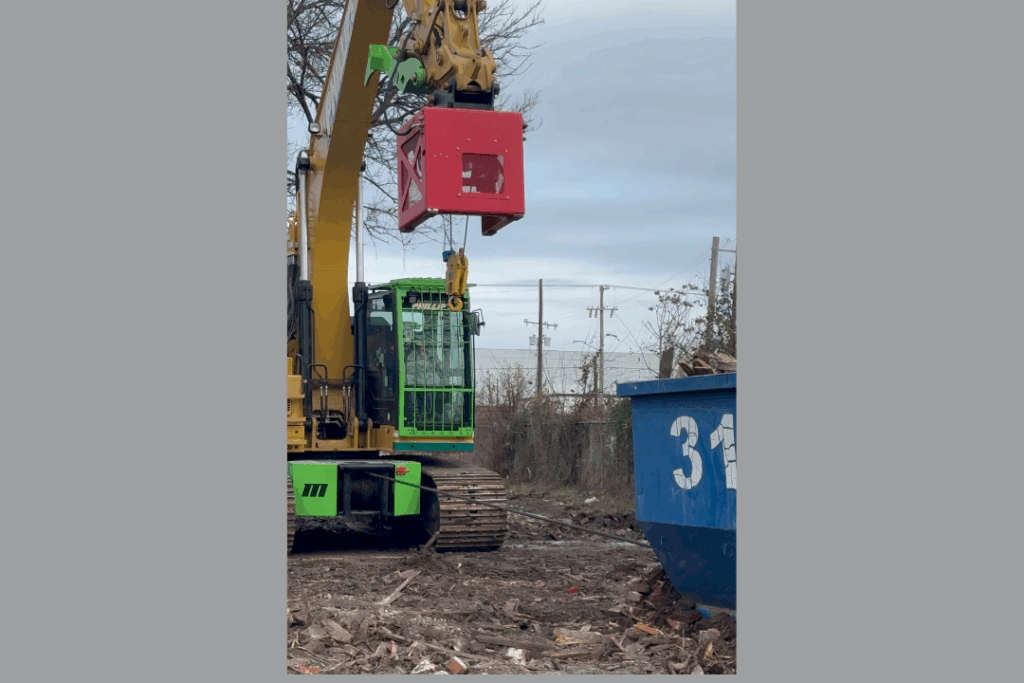

This powerhouse addition transforms a standard excavator into a multi-functional workhorse, capable of pulling, lifting, recovering, and securing heavy loads. It’s built for operators who need strength, control, and reliability on every jobsite.

Turning Your Excavator Into a Multi-Tasking Machine

Your excavator is already a cornerstone of productivity. It digs, lifts, and handles materials day in and day out. But when equipped with a Midwestern Manufacturing Excavator Winch Attachment, that same machine gains the ability to handle recovery, towing, and hoisting operations—all with precision and safety.

Instead of mobilizing a separate winch truck or crane, one excavator can now take on multiple roles, reducing transport costs and simplifying logistics. Contractors in forestry, pipeline construction, utilities, and mining are finding that this single upgrade allows them to streamline operations, reduce downtime, and complete projects faster.

When every piece of equipment can do more, your entire fleet becomes more profitable.

Designed and Built by Midwestern Manufacturing

At Midwestern Manufacturing, we don’t just build attachments—we engineer performance. Each Excavator Winch Attachment is designed in-house and manufactured to endure the toughest jobsite conditions. From the drum and gearbox to the mounting system, every component is tested to handle demanding loads with exceptional control and longevity.

We use precision-machined steel, corrosion-resistant finishes, and sealed gear housings that keep performance consistent even in mud, snow, or heavy moisture environments. Our attachments integrate seamlessly with most standard excavator models and hydraulic systems, offering simple installation and low maintenance requirements.

Operators appreciate the control and confidence our systems deliver. With options for hydraulic or electric actuation, line pull capacities ranging from moderate to heavy-duty, and intuitive cab controls, every attachment is designed to make challenging work easier—and safer.

Built for Strength, Safety, and Control

When it comes to winching, power without control can be dangerous. That’s why every MidwesternManufacturing Excavator Winch Attachment is equipped with safety-first features such as dual automatic load-holding brakes, pressure-relief systems, and precision control valves. These features ensure smooth, controlled operation during lifting or pulling tasks, minimizing risk to both operators and equipment.

Safety guidelines from organizations like the Occupational Safety and Health Administration (OSHA) emphasize the importance of mechanical control and load stability when using powered winching equipment. Our engineering approach aligns with those principles, ensuring each winch operates safely and reliably under pressure.

We also design for serviceability—accessible grease points, heavy-duty bearings, and simplified hose routing make routine maintenance fast and cost-effective.

Real-World Performance on the Jobsite

The difference our attachments make becomes obvious the moment they hit the field. Across a range of industries, contractors are using Midwestern Manufacturing’s Excavator Winch Attachments to boost performance and efficiency:

- Pipeline Construction: Pull and position sections of pipe across rugged or uneven terrain without extra lifting equipment.

- Forestry and Land Clearing: Retrieve logs or assist other machines on steep or unstable ground with controlled line tension.

- Recovery Operations: Free stuck machines quickly, safely, and independently—no waiting for a separate recovery vehicle.

- Utility and Infrastructure Projects: Secure, tension, or lift materials in confined workspaces where cranes can’t easily operate.

Each of these applications showcases how this single attachment can save hours of work, reduce wear on your fleet, and keep projects moving forward even in the most demanding conditions.

Proven ROI and Operational Savings

Investing in an Excavator Winch Attachment isn’t just about adding another tool—it’s about boosting return on investment. By extending your excavator’s functionality, you reduce the need to purchase or rent additional specialized equipment. That means fewer machines to transport, fuel, and maintain.

The attachment also allows operators to complete multiple phases of work without switching machinery or waiting for external help, translating directly into faster completion times and lower labor costs. For contractors working in remote or high-demand environments, this upgrade often pays for itself in a single project season.

According to the U.S. Bureau of Labor Statistics, productivity improvements in the construction sector are closely linked to better equipment utilization. That’s exactly what Midwestern Manufacturing’s attachments are designed to deliver—more output, less downtime, and maximum jobsite control.

Operator-Focused Innovation

We know operators are the heartbeat of every jobsite. That’s why every feature we design—from ergonomic control levers to line-speed adjustability—is centered on operator safety and comfort. The ability to handle heavy pulls from the cab reduces manual cable handling and exposure to hazardous conditions.

Smooth operation, stable winching control, and efficient setup times make this attachment a favorite among field crews who value reliability and ease of use.

When operators can trust their equipment, they work faster, safer, and with greater confidence. That’s exactly what Midwestern Manufacturing delivers.

Choosing the Right Winch for Your Fleet

Every jobsite is different, and so are your performance needs. Midwestern Manufacturing offers a range of Excavator Winch Attachment models with varying line pull capacities, cable options, and hydraulic configurations. Whether you need high-capacity pulling power for recovery or moderate-duty performance for lifting applications, our engineering team can help you select the best fit for your excavator model and workload.

We take pride in offering direct consultation and custom configuration options—because no two operations are alike, and we believe your equipment should be built for your exact demands.

Why Contractors Trust Midwestern Manufacturing

With decades of experience in heavy equipment design, Midwestern Manufacturing has built a reputation for quality, integrity, and customer commitment. Our products are made to last, and our support team stands behind every attachment we build. We don’t just sell equipment—we build long-term partnerships with contractors who expect their tools to work as hard as they do.

When you choose a Midwestern Manufacturing attachment, you’re choosing American-engineered reliability, field-tested performance, and a company that understands the challenges of real-world construction.

Power Your Fleet with Midwestern Manufacturing

Upgrading your excavator with a Midwestern Manufacturing Excavator Winch Attachment is one of the smartest moves you can make to improve efficiency, versatility, and ROI. It transforms a single machine into a true multi-tasking asset—ready to pull, lift, or recover whenever and wherever the job demands it.

Don’t let downtime or equipment limitations hold your project back. Contact Midwestern Manufacturing today to learn more about our winch attachment models, custom solutions, and dealer options. Power your fleet forward with the strength, reliability, and innovation that only Midwestern Manufacturing delivers.

Author: Doug G.

Comments are closed.