When to Use a Dual Line Sagging Winch

Understanding the Value of Specialized Tension Equipment

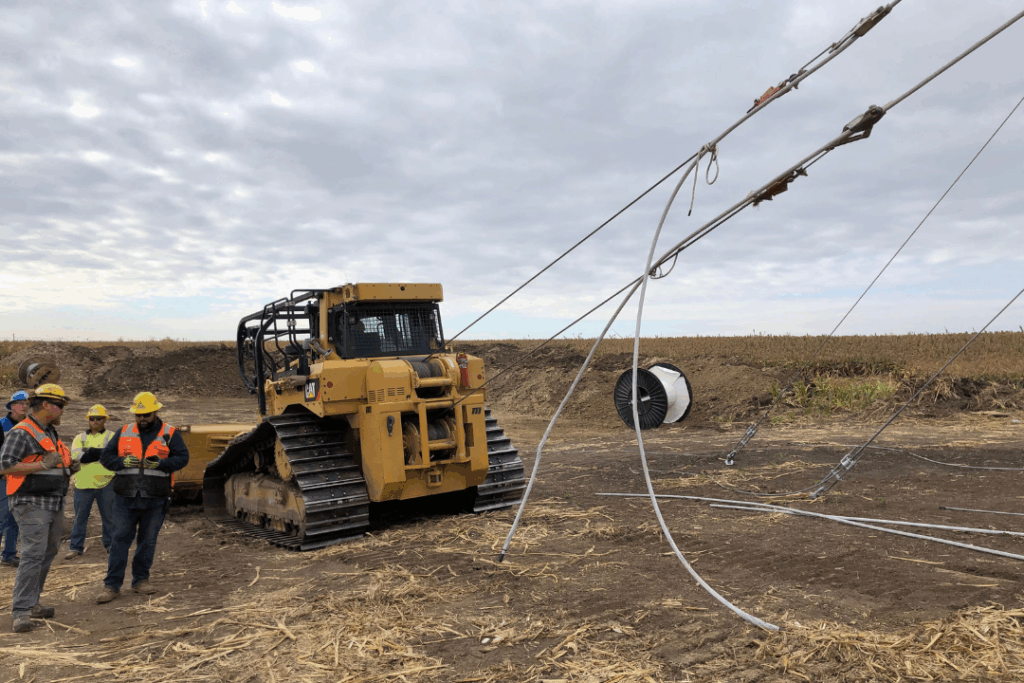

At Midwestern Manufacturing, we build tools that support transmission line crews working under demanding conditions. Modern electrical infrastructure projects often involve longer spans, heavier conductors, complex terrain, and tighter engineering requirements than ever before. While a single-line winch is sufficient for basic sagging needs, many jobsite challenges call for equipment with greater precision and control. That’s where a Dual Line Sagging Winch becomes the right choice. By delivering synchronized tension across two lines, it helps crews maintain balance, prevent conductor twist, and achieve smoother, more controlled adjustments during installation. When the job requires stability beyond what standard tensioning methods can offer, this tool becomes an essential asset for maintaining efficiency and safety.

When Load Distribution Needs Greater Stability

Conductor behavior during installation can be unpredictable, especially in long spans or with bundled or heavier conductors. Single-line systems may struggle to manage shifting weight or lateral movement, which can create safety concerns and alignment challenges. A Dual Line Sagging Winch provides additional points of control, helping stabilize the conductor and reduce twisting or swaying. Balanced tension makes it easier for operators to fine-tune placement while ensuring that the conductor settles evenly across the span. This improved control supports higher-quality installations and reduces the likelihood of rework.

When Terrain Conditions Complicate Sagging

Transmission routes often traverse hills, slopes, valleys, and uneven footing that complicate conductor handling. Terrain-related tension variations can make it difficult for crews to achieve uniform sag, leading to delays or repeated adjustments. A Dual Line Sagging Winch solves this problem by allowing operators to adjust each line independently to counteract terrain-driven imbalances. Whether crews are working across steep grades or navigating changes in elevation, this flexibility helps maintain proper sag and alignment. Independent control also enables safer installations in areas where environmental conditions place extra stress on the conductor.

When Working With Heavier or High-Capacity Conductors

As power systems expand and voltages rise, many projects now use larger, heavier conductors or bundled configurations that require more advanced tensioning equipment. These installations place greater load on winches and support machinery, making single-line systems less effective. A Dual Line Sagging Winch provides the strength needed to handle heavier conductors without sacrificing precision. With two controlled tension points, the system distributes weight more evenly and prevents overloading, helping crews achieve consistent sag across long spans. This improves both safety and accuracy during the installation of high-capacity lines.

When Precision Placement Is Critical

For many transmission projects, precision is not optional—it is a functional requirement. Engineers specify exact sag values to maintain phase spacing, clearance, and safe mechanical loading under all operating conditions. Meeting these specifications requires a tool capable of fine adjustments. A Dual Line Sagging Winch offers that level of control, allowing crews to reach design sag accurately and efficiently. These capabilities align with the engineering criteria outlined by organizations such as the Institute of Electrical and Electronics Engineers and help ensure that each conductor performs reliably once energized.

When Safety Requires More Controlled Line Movement

Safety is a top priority in every transmission installation, and conductor movement during sagging is one of the most sensitive phases of the project. Uncontrolled shifts can create hazards for ground crews and linemen working on structures. By stabilizing conductor behavior, a Dual Line Sagging Winch reduces these risks significantly. Balanced tension prevents sudden motions, reduces swing, and creates smoother line transitions, which improves crew confidence and situational awareness. These safety gains support the principles promoted by the Occupational Safety and Health Administration and help maintain predictable operations on the jobsite.

When Minimizing Rework is Essential

Rework is one of the most costly setbacks in transmission construction. Misalignment, improper sag, or unstable tensioning often forces crews to redo previous steps, leading to lost productivity and increased labor expenses. A Dual Line Sagging Winch helps eliminate these problems through reliable, repeatable tension control. With steadier handling and greater stability, crews achieve correct sag on the first attempt and avoid the time-consuming process of resetting hardware or repositioning conductors. This not only improves jobsite efficiency but also strengthens overall project outcomes.

When Coordinating Large Crews and Multiple Equipment Types

Transmission work requires coordination among linemen, rigging teams, pulling operators, inspectors, and heavy equipment operators. Clear communication and predictable conductor behavior are essential for maintaining workflow. A Dual Line Sagging Winch promotes this coordination by delivering tensioning performance that operators and ground crews can anticipate. With smoother adjustments and more consistent behavior, teams stay aligned and work more effectively across multiple spans. Inspectors encounter fewer issues, operators can position machinery confidently, and supervisors gain better visibility into the project’s progression.

When Weather Conditions Add Complexity

Environmental conditions play a major role in conductor handling. Wind can cause drift or sway, temperature shifts can affect tension, and uneven ground conditions may influence how a conductor settles during sagging. A Dual Line Sagging Winch provides needed stability in these scenarios by allowing operators to adjust tension on each line to counteract environmental impacts. Whether crews face gusty conditions or varying terrain, the dual-line setup offers more control and helps maintain progress even when weather challenges arise.

When Spans Include Angles, Curves, or Elevation Changes

Transmission lines often follow routes with complex geometric requirements, including angles, bends, elevation transitions, and variable structure spacing. These design elements demand precise sag control to preserve conductor integrity and maintain proper loading. A Dual Line Sagging Winch makes it easier to navigate these scenarios by offering independent tension adjustments that allow crews to shape conductor placement accurately. With better control through complicated routing, crews maintain engineering compliance and reduce the likelihood of structural strain.

When the Project Demands Advanced Tension Control

Not every installation requires a dual-line approach, but many of today’s larger or more technical projects benefit significantly from the additional control it provides. From long-span transmission lines to renewable energy interconnections to heavy bundling configurations, the demands of modern infrastructure often exceed the capabilities of single-line systems. At Midwestern Manufacturing, we design the Dual Line Sagging Winch to meet these elevated requirements and give crews the precision and power needed to complete their work efficiently.

Equip Your Crew with the Tools for Precision and Stability

A Dual Line Sagging Winch gives line crews the accuracy, stability, and confidence required for complex transmission installations. Whether you’re working across rugged terrain, handling heavy conductors, or meeting strict engineering specifications, this tool strengthens every stage of the sagging process. At Midwestern Manufacturing, we engineer equipment to help crews work safer, faster, and more effectively, and when you’re ready to elevate performance on your next project, choose the tool that delivers balanced control and put a Dual Line Sagging Winch to work with total confidence today.

Author: Doug G.

Comments are closed.