Hydraulic Winches: How They Work and Where They’re Used

Why Hydraulic Winching Plays a Critical Role in Heavy-Duty Work

At Midwestern Manufacturing, we design equipment for industries where reliability, control, and endurance matter every day. Across construction, energy, recovery, marine, and infrastructure projects, crews rely on winching systems that perform consistently under pressure. A hydraulic winch stands out because it delivers controlled pulling force through fluid power rather than electrical current, making it well suited for demanding environments. Understanding how these systems work and where they are used helps operators select equipment that improves safety, efficiency, and long-term performance.

How Hydraulic Winches Generate Pulling Force

Hydraulic winching systems convert fluid pressure into mechanical movement. Instead of relying on electric motors, these systems use pressurized hydraulic fluid to drive the winch drum. This allows for smooth, controlled operation even under heavy load. The process works through coordinated system components that regulate pressure, speed, and direction.

Key elements of hydraulic winch operation include:

- A hydraulic pump that generates fluid pressure

- Control valves that regulate flow and direction

- A hydraulic motor that converts pressure into rotational force

- A drum that winds or unwinds cable with controlled tension

- A braking system that holds loads securely when movement stops

Because fluid pressure remains consistent, operators benefit from steady torque delivery and precise control, which is especially important during slow, high-load pulls.

Why Hydraulic Systems Excel Under Continuous Load

One of the biggest advantages of hydraulic systems is their ability to perform under sustained workloads. Electric winches often struggle with heat buildup during extended use, but hydraulic systems manage heat more effectively through fluid circulation. A hydraulic winch can maintain pulling power across long duty cycles without loss of performance. This capability makes hydraulic systems ideal for industrial tasks that require repeated or prolonged pulling rather than short, intermittent use.

Safety Benefits of Controlled Load Movement

Handling heavy loads safely requires predictable equipment behavior. Hydraulic winching systems allow operators to fine-tune speed and tension, reducing shock loads and sudden movement. This predictability helps protect crews, anchor points, and surrounding structures. Controlled starts and stops also reduce stress on cables and components, extending equipment life. These safety-focused handling practices align with material-handling principles promoted by the Occupational Safety and Health Administration, which emphasizes stable load control and proper equipment selection.

Construction Applications That Depend on Hydraulic Winching

Construction sites often demand pulling power that can operate reliably in dust, moisture, vibration, and uneven terrain. Hydraulic winching systems are frequently integrated into heavy machinery or fixed installations to support a wide range of construction tasks. A hydraulic winch is commonly used for:

- Positioning large structural components

- Assisting with foundation and formwork placement

- Pulling heavy materials into alignment

- Supporting lifting operations where precise control is required

Because hydraulic systems resist environmental stress better than many electric alternatives, they remain dependable throughout long workdays in harsh conditions.

Energy and Infrastructure Project Use Cases

Energy and infrastructure projects place extreme demands on equipment. Pipeline installation, utility construction, and large-scale infrastructure development often occur in remote locations where electrical power is limited or unreliable. Hydraulic systems integrate easily with existing equipment and deliver consistent torque for tensioning and pulling tasks. Engineering guidance from organizations such as the American Society of Mechanical Engineers emphasizes controlled mechanical performance, which hydraulic winching systems naturally support through steady force application.

Recovery and Heavy Equipment Operations

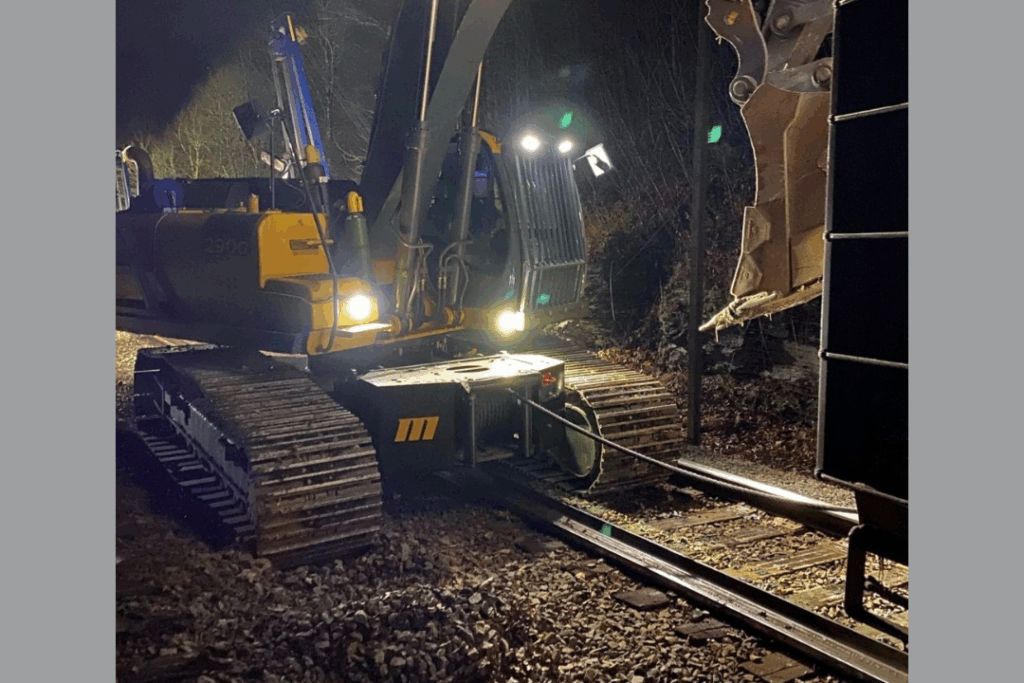

Recovery operations require equipment that can adapt to unpredictable conditions. Loads may shift suddenly, terrain may be unstable, and time pressure is often high. A hydraulic winch provides smooth, controllable force that allows operators to respond safely as conditions change. Common recovery applications include:

- Vehicle and rail equipment recovery

- Repositioning disabled machinery

- Stabilizing loads during emergency response

- Controlled pulling in confined or uneven environments

The ability to deliver steady torque without abrupt changes makes hydraulic systems particularly valuable during recovery scenarios where safety margins are tight.

Marine and Offshore Environments

Marine and offshore settings expose equipment to constant moisture, salt, and movement. Hydraulic winching systems are widely used in these environments because they resist corrosion and maintain performance under continuous load. Typical applications include:

- Mooring and anchoring operations

- Cargo handling and positioning

- Offshore support and deck operations

The sealed nature of hydraulic systems helps protect internal components, making them a preferred choice where environmental exposure would quickly degrade less robust equipment.

Hydraulic vs Electric Winching Systems

Electric winches are effective for lighter-duty tasks, but they can be limited by duty cycle, power availability, and heat buildup. Hydraulic systems deliver higher torque at lower speeds and sustain performance over extended periods. A hydraulic winch also integrates directly with hydraulic circuits already present on heavy equipment, eliminating the need for additional electrical infrastructure. This flexibility allows operators to scale performance based on real-world demands rather than power constraints.

Long-Term Durability and Cost Efficiency

Durability is a major factor in overall operating cost. Hydraulic winching systems are built with heavy-duty components designed to withstand repeated high-load cycles. Reduced thermal stress and simplified mechanical layouts contribute to longer service intervals and fewer unexpected failures. Over time, this durability translates into lower maintenance costs, less downtime, and more predictable equipment ownership expenses.

Selecting the Right Winch for the Application

Winching applications vary widely, making proper selection critical. Factors that influence the right configuration include:

- Required load capacity

- Line speed and control needs

- Environmental exposure

- Expected duty cycle

- Integration with existing equipment

At Midwestern Manufacturing, we focus on designing systems that match real operating conditions rather than theoretical limits. Selecting the correct hydraulic winch ensures optimal performance, protects surrounding equipment, and supports safe, efficient operation throughout the job.

Built for Real-World Performance

Hydraulic winching systems continue to be trusted across construction, energy, recovery, and marine industries because they deliver reliable pulling power where it matters most. At Midwestern Manufacturing, we engineer winching solutions that combine strength, precision, and durability to meet the demands of real jobsites. When your operation depends on controlled force, consistent performance, and long-term reliability, choose equipment built for the work and put proven hydraulic winching technology to work with confidence today.

Author: Doug G.

Comments are closed.