Understanding the Dozer ‘Sag’ Winch: What It Is

In the world of powerline construction, precision and control make all the difference. Whether you’re tensioning new transmission lines across open fields or working on challenging terrain, having reliable, controlled line pull is essential. That’s where the Dozer ‘Sag’ Winch from Midwestern Manufacturing comes in.

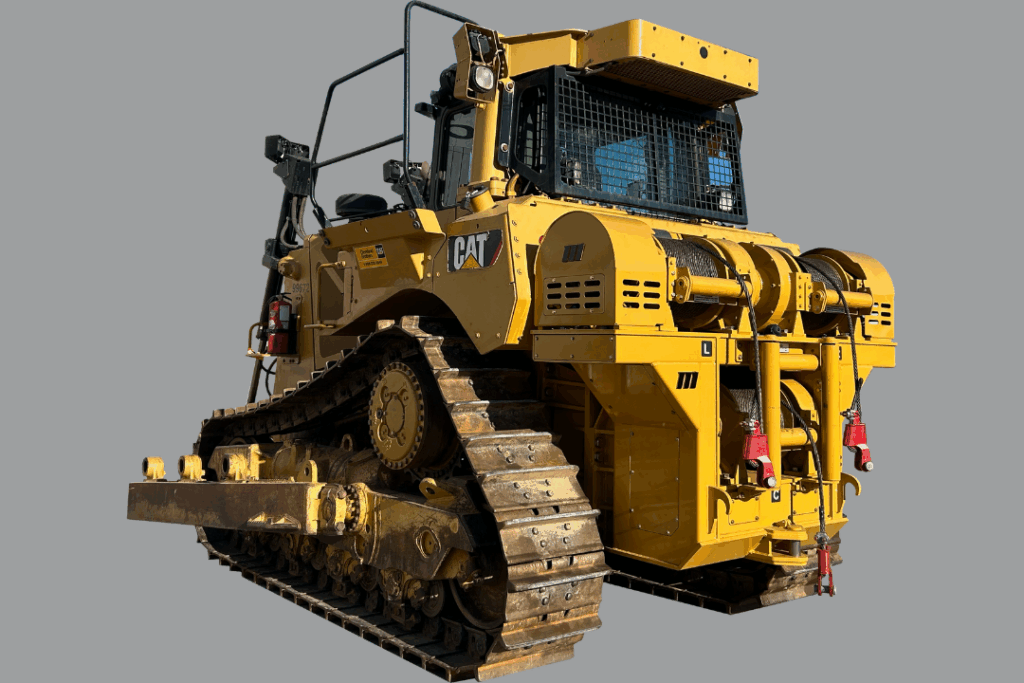

Designed specifically for pulling and tensioning power transmission lines, Midwestern Manufacturing’s winch attachments deliver unmatched power, precision, and safety. Available in dual and triple winch configurations, these attachments can be mounted on a variety of dozer models and provide line pull capacities of up to 50,000 pounds. For contractors working in rugged environments or remote right-of-way projects, the Dozer “Sag” Winch is a tool that turns efficiency and reliability into standard operating procedure.

What Is a Dozer ‘Sag’ Winch?

A Dozer ‘Sag’ Winch is a heavy-duty attachment that enables operators to pull and tension transmission lines during powerline installation and maintenance projects. Mounted to the rear of a dozer, it provides controlled line movement that allows crews to sag wire accurately between towers or poles.

This attachment is essential for line sagging—a process where wire is tensioned and adjusted to achieve the correct amount of sag between structures, ensuring the line maintains the right tension and clearance. With Midwestern Manufacturing’s winch attachments, this process is both safer and more efficient, giving operators precise control directly from the cab.

Each winch operates using the dozer’s existing hydraulic system, which eliminates the need for external power sources. This integration allows for smooth, controlled pulling with the strength and stability of the dozer as the foundation.

Built for Power and Precision

Midwestern Manufacturing’s Dozer ‘Sag’ Winch attachments are engineered to perform in demanding environments. Whether your crew is working across rolling hills, soft ground, or rocky terrain, these winches are built to maintain consistent tension and control throughout the line-pulling process.

Each model features hydraulic planetary winches with easy-to-use integrated cab controls. Operators can control multiple winches simultaneously and adjust line speed or direction as needed. The built-in two-speed switch allows for fast spooling and precision tensioning, depending on the task at hand.

With line pull capacities up to 50,000 pounds, these attachments provide the muscle needed to handle heavy wire loads without sacrificing accuracy or safety.

Configurations for Every Application

Midwestern Manufacturing offers both dual and triple winch configurations to fit the requirements of different projects and wire setups:

- M50DLSW (Dual Winch Attachment): Ideal for smaller-scale or single-circuit line pulls, this configuration provides reliable power and control for moderate sagging operations.

- M50TLSW (Triple Winch Attachment): Designed for large-scale transmission line projects, this configuration allows for multiple wire pulls simultaneously, maximizing productivity and minimizing setup time.

Both models are compatible with popular dozer platforms like the CAT D6, D8 and John Deere 750/850/950, and can be installed using the dozer’s standard rear mount pin-up system.

Features That Define Performance

Midwestern Manufacturing’s Dozer ‘Sag’ Winch attachments are packed with features that improve safety, usability, and performance on the jobsite:

- Integrated cab controls allow operators to control winches simultaneously for precise tensioning.

- Built-in two-speed operation provides both fast line spooling and slow, controlled pulls.

- Free spool mechanism enables the wire rope to be pulled freely to the connection point.

- Tension rollers on each winch prevent wire rope from bird-nesting and ensure smooth feeding.

- 3/4” x 300 ft (6 x 37 EIPS, IWRC) wire rope is installed on each winch, delivering strength and reliability.

- Direct hydraulic integration with the dozer’s existing system means no external power source is required.

- Line pull capacity up to 50,000 lbs. ensures enough force for even the most demanding line-pulling applications.

These thoughtfully designed features make Midwestern Manufacturing’s sagging winch systems easy to operate, maintain, and trust—job after job.

Safety First—Every Time

Safety is built into every Midwestern Manufacturing product, and the Dozer ‘Sag’ Winch is no exception. The system’s integrated hydraulic controls and tension rollers are designed to maintain steady, predictable line pull, preventing sudden releases or wire slack that could endanger crews.

Operators stay protected inside the cab, where they can manage all winch functions remotely. The free spool mechanism allows line setup and connection to be done safely without manually feeding wire under tension.

These safety-driven design elements align with Occupational Safety and Health Administration (OSHA) best practices, giving line crews confidence that every pull is performed under controlled, stable conditions.

Built to Last in Harsh Environments

Midwestern Manufacturing’s reputation for durability is built on decades of real-world experience. Every winch system is constructed from high-strength materials and finished with corrosion-resistant coatings to withstand exposure to dirt, moisture, and extreme temperatures.

Sealed gear assemblies keep internal components protected from dust and debris, while heavy-duty bearings ensure smooth, consistent performance even under continuous load. Whether working in heat, cold, or wet conditions, you can count on these attachments to perform day in and day out.

Real-World Advantages

Contractors across the utility and energy sectors rely on Midwestern Manufacturing’s winch attachments for one simple reason—they work. Crews using the Dozer ‘Sag’ Winch report faster setup times, improved pulling consistency, and less downtime due to maintenance or equipment failure.

Because the winch draws power directly from the dozer’s hydraulic system, operators experience responsive, precise control that helps maintain uniform sag across long stretches of line. For large-scale transmission projects, that consistency translates to fewer adjustments, less rework, and greater overall efficiency.

Engineered and Supported in the USA

All Midwestern Manufacturing attachments are designed, engineered, and built in the United States. Our products are backed by decades of innovation and a commitment to quality craftsmanship. We don’t just sell equipment—we partner with contractors to ensure every system performs exactly as promised.

From initial consultation to post-sale support, our technical experts are here to help configure the right solution for your fleet and ensure you get the maximum value out of your investment.

The Bottom Line: Power, Precision, and Reliability

The Dozer ‘Sag’ Winch from Midwestern Manufacturing is more than just an attachment—it’s a productivity tool that helps utility and transmission line contractors get the job done faster, safer, and more efficiently. With configurations to fit most major dozer models and line pull capacities up to 50,000 pounds, it’s built to meet the toughest demands of modern powerline work.

Don’t let your project slow down due to unreliable tensioning equipment. Equip your fleet with the proven performance of Midwestern Manufacturing’s sagging winch systems.

Contact Midwestern Manufacturing today at 918-858-4201 or visit sidebooms.com to learn more about our dozer-mounted winch attachments, available configurations, and dealer support network. Experience the difference that American engineering, reliability, and precision can make on your next powerline project.

Author: Joe B.

Comments are closed.