How a Line Sagging Winch Improves Jobsite Efficiency

Meeting Modern Jobsite Demands with Smarter Tools

At Midwestern Manufacturing, we know today’s transmission line crews operate under demanding conditions. The push for expanded electrical infrastructure, grid modernization, and renewable integration has created a higher volume of projects with tighter deadlines and more complex requirements. In this fast-paced environment, having the right equipment is essential for keeping work efficient, safe, and precise. A Line Sagging Winch gives crews controlled, consistent tension during conductor installation, helping them achieve proper sag, alignment, and wire handling across every structure. When every adjustment affects long-term performance, reliability, and safety, this tool becomes indispensable.

The Power of Controlled Tension in Transmission Line Work

Accurate sagging is one of the most critical steps in overhead line construction. Too much sag reduces clearance; too little increases tension and risks overstressing towers or hardware. A Line Sagging Winch allows operators to make precise adjustments that ensure each conductor meets design values set by engineering standards and industry guidelines like those shared by the Institute of Electrical and Electronics Engineers. Manual or outdated methods introduce inconsistencies that slow down progress and can result in costly rework. With reliable tension control, the conductor settles where it needs to be, supporting proper electrical performance and structural reliability for decades to come.

Why Inconsistent Sag Creates Significant Project Delays

Small variations in sag can create a ripple effect across an entire span. If crews notice improper clearances or uneven conductor tension after a section is installed, they must stop, reassess, and often reset equipment. This process adds hours or even days to project timelines. The Line Sagging Winch eliminates many of these issues by providing predictable adjustments that position the conductor correctly on the first attempt. Correct sag improves phase spacing, minimizes mechanical stress, and helps ensure compliance with design specifications. By reducing the need for time-consuming corrections, crews can maintain momentum across long distances.

Reducing Physical Strain on Line Crews

Transmission line installation demands both technical skill and physical endurance. Manually managing conductor tension or making repeated adjustments can quickly wear crews down, especially in long spans or rugged terrain. A Line Sagging Winch handles the heavy pulling, holding, and incremental tensioning so lineworkers can focus on monitoring rather than physical effort. This reduces fatigue, lowers injury risk, and helps maintain consistent productivity throughout the day. With easier load management, crews stay sharper and safer, supporting higher-quality work in challenging conditions.

Creating a Safer, More Predictable Jobsite

Safety is the foundation of every project in the transmission industry. When tension is managed by hand or with improvised tools, sudden shifts or unexpected conductor movement can put workers at risk. A Line Sagging Winch provides smooth, controlled motion that operators can anticipate, allowing them to execute each phase with confidence. Predictable tension also improves communication between crew members, since everyone understands how the conductor will move and respond during adjustments. These improvements align with the safety guidance promoted by the Occupational Safety and Health Administration and help ensure that risk stays low throughout installation.

Eliminating the Need for Constant Readjustments

Few things slow down transmission line construction more than frequent repositioning of equipment or repeated sag checks. Without stable tension control, conductors may drift, slip, or settle unevenly as crews move from structure to structure. A Line Sagging Winch maintains consistent hold and tension across each phase, minimizing the need for stops and resets. This steadiness keeps the conductor where it needs to be while crews complete related tasks such as clipping-in, spacer installation, or messenger wire adjustments. The result is smoother workflow, fewer disruptions, and stronger alignment with project schedules.

Improving Coordination Among Transmission Teams

Building overhead lines requires seamless collaboration between operators, riggers, ground technicians, linemen, inspectors, and supervisors. When tension control is inconsistent, coordination becomes difficult and communication slows. With a Line Sagging Winch providing stable, predictable output, teams work in better harmony. Operators can position machinery with confidence, inspectors face fewer concerns, and line crews can predict how equipment will respond at each step. Clear coordination reduces bottlenecks and helps keep multi-structure segments moving efficiently from pulling to sagging to clipping.

Supporting Long-Term Grid Performance

Every conductor plays a role in the reliability of the electrical grid. If sag or tension is even slightly off, long-term performance can be compromised through excessive vibration, uneven loading, or reduced clearance during temperature changes. Using a Line Sagging Winch ensures that the conductor settles with even support along the span. This promotes proper galloping resistance, reduces stress on insulators and hardware, and supports the mechanical life of the conductor. With accurate installation, inspections become smoother and long-term maintenance becomes more predictable, helping utilities deliver consistent service to their customers.

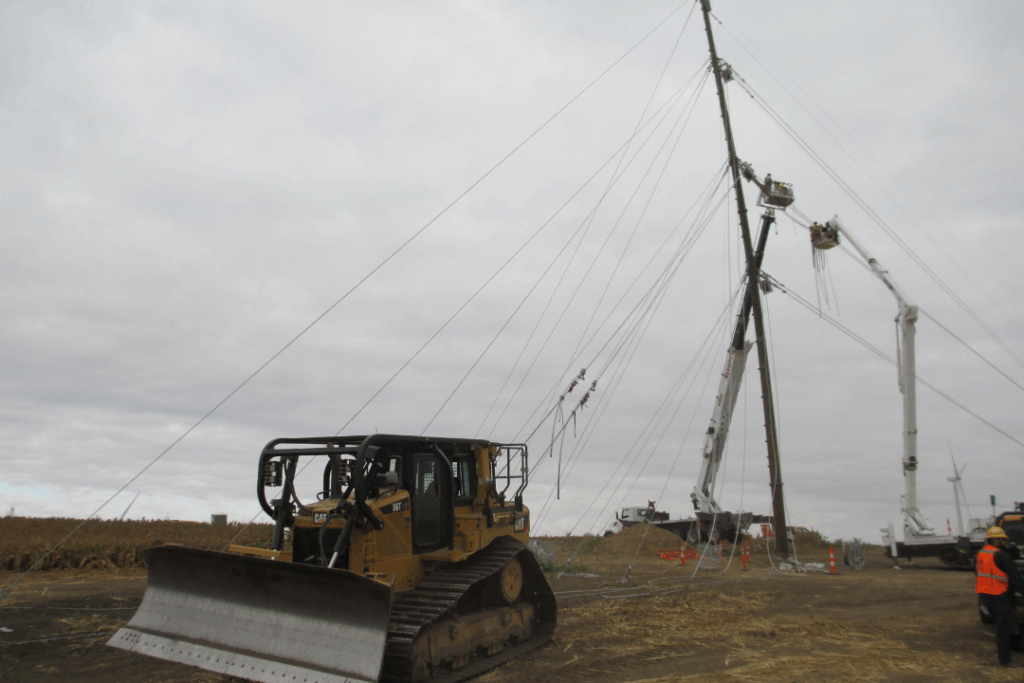

Built for Harsh Conditions and Demanding Terrain

Transmission lines often run across remote, rugged, or weather-exposed locations. Equipment must withstand harsh conditions, changing temperatures, and uneven ground. A Line Sagging Winch is engineered to deliver steady performance despite these challenges. Its durability ensures reliable operation during long pulls and extended tensioning cycles, even in environments where wind, terrain, or elevation complicate the work. Crews can depend on the winch to perform day after day, reducing downtime caused by equipment limitations and keeping the project on track.

Why Reliability Drives Jobsite Efficiency

Predictability is one of the most powerful advantages a jobsite can have. When equipment behaves consistently, crews can work faster, supervisors can plan more effectively, and operators can execute tasks without hesitation. A Line Sagging Winch provides that stability through reliable tension control that removes uncertainty from the sagging process. This consistency supports steady workflow, accurate scheduling, and stronger overall productivity. Reliable tools lead directly to reliable outcomes, and that reliability matters on every structure and every mile of line.

Delivering Better Results Across All Phases of Installation

From conductor pulling to final clipping, tension control affects nearly every stage of overhead line construction. A Line Sagging Winch improves quality, reduces rework, enhances safety, and strengthens communication across the jobsite. At Midwestern Manufacturing, we believe the right equipment makes the difference between projects that struggle and projects that run smoothly. With dependable tension control, crews deliver cleaner spans, better alignment, and stronger long-term performance.

Moving Your Crew Toward Greater Efficiency

In the competitive world of electrical transmission construction, efficiency is essential. A Line Sagging Winch is one of the most effective investments a crew can make to improve workflow, minimize delays, and increase precision during conductor installation. At Midwestern Manufacturing, we build equipment that keeps you working smarter, safer, and faster. When you’re ready to elevate your tension control process and bring greater efficiency to every span, choose the tool that delivers professional results and move your project forward with confidence today.

Contact Midwestern Manufacturing today to learn more.

Author: Joe B.

Comments are closed.